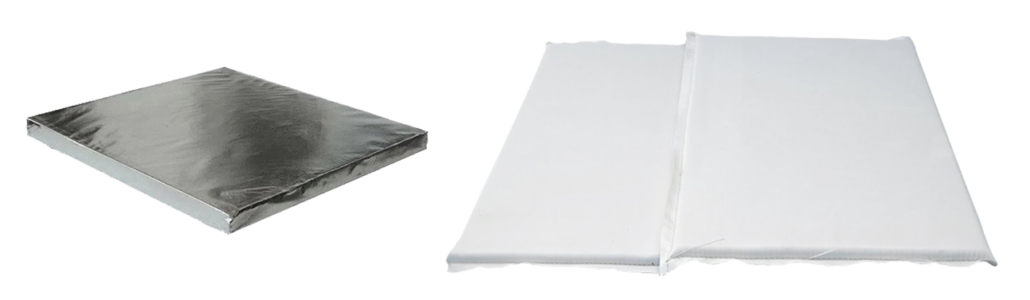

Microporous ceramic fiber board manufactured by Ravani Ceramics are designed for insulation purpose for high-temperature applications. These boards have high compressive strength and they are covered with aluminium foil or glass fiber cloth. Its mineral structure is designed for applications where lowest shrinkage upto temperature of 1000 °C is required.

Because of the most advanced technology used for manufacturing of these boards, the thermal shock handling property of this board is extremely good. It’s thermal conductivity coefficient is also very low which makes it an excellent insulation material even if the thickness is very less. As it can provide insulation at low thickness as compared to other insulation boards, it occupies less space and implies less weight in the application in which it is used.

Ravani Ceramics manufacture two variants of this board. One is water receptive and the other is water resistant. The water resistant variant has the water resistance properties throughout its entire volume. It can stay resistant to water at a temperature of 250 °C. However, the moisture in the surrounding environment does affect the performance of any of the two variants.

These boards are also known as Microporous Nano Thermal Insulation Board and also as Ultra Plus Panels.

Key Features

- High Temperature Resistance:

These boards are capable of withstanding very high temperatures, making them suitable for applications where traditional insulating materials might fail. - Low Thermal Conductivity:

Microporous ceramic fiber boards typically have low thermal conductivity, meaning they can effectively reduce heat transfer and provide insulation. - Lightweight:

These boards are often lightweight, which makes them easy to handle and install. - Microporous Structure:

The term “microporous” indicates the presence of small pores or voids within the material. This structure contributes to enhanced insulation properties. - Chemical Resistance:

Many microporous ceramic fiber boards exhibit resistance to certain chemicals, adding to their versatility in various environments. - Low Heat Storage:

The low heat storage capacity of these boards means that they heat up and cool down relatively quickly.

Applications

Microporous boards find versatile applications across various industries due to their excellent thermal insulation properties. Here’s how they are used in different applications:

- Pipe Insulation:

Microporous boards are employed for insulating pipes to prevent heat loss, ensuring efficient energy utilization in industrial processes and HVAC systems. - Fire Protection:

Microporous boards act as fire-resistant barriers, offering protection in critical areas and preventing the spread of flames. - Insulation for Curved Surfaces of High Temperature:

The flexibility and adaptability of microporous boards make them suitable for insulating curved surfaces in high-temperature environments, ensuring consistent insulation coverage. - Furnace Walls and Equipment:

Microporous boards are used to insulate furnace walls and equipment, contributing to energy efficiency and maintaining high temperatures within the furnace. - Observation of Industrial Furnace:

Microporous materials may be used for insulating observation windows in industrial furnaces, ensuring clarity while maintaining thermal insulation. - Industrial Furnace Burner, Door:

These boards provide insulation for furnace burners and doors, aiding in temperature control and energy conservation. - Plug and Launder of Aluminum Products Industry:

Microporous boards are used in the aluminum industry for insulation in plugs and launders, contributing to energy-efficient processing. - Lining Refractory of High-Temperature Laboratory Furnace:

In laboratory settings, microporous boards serve as insulation in the lining of high-temperature furnaces, maintaining controlled experimental conditions. - Thermal Insulation of Domestic and Industrial Heating Devices:

Microporous boards contribute to the thermal insulation of both domestic and industrial heating devices, enhancing energy efficiency. - Non-Ferrous Metal Melting Tank Padded, Casting Riser:

In metal casting applications, microporous boards insulate melting tanks and casting risers, ensuring controlled and efficient metal processing. - Roller Furnace Insulation Bricks:

Microporous boards are utilized in roller furnace applications, providing insulation to maintain high temperatures and improve overall furnace efficiency.

Size Details

Available Sizes mm [inch] :

1000 (L) x 1000 (W) [39.3 (L) x 39.3 (W)]

1000 (L) x 600 (W) [39.3 (L) x 23.6 (W)]

915 (L) x 610 (W) [36.0 (L) x 24.0 (W)]

And Many more custom sizes can also be crafted on demand

Thickness mm [inch] :

10, 12, 15, 17, 20, 25, 30, 35, 40, 45, 50

[0.4, 0.5, 0.6, 0.7, 0.8, 1, 1.18, 1.37, 1.57, 1.77, 2]